Stainless steel fork type rotating cargo hook

304 316 stainless steel fork type rotating cargo hook

Excellent corrosion resistance

304 stainless steel: With excellent rust and corrosion resistance, it is suitable for most conventional warehousing, logistics, and industrial environments.

316 stainless steel: contains molybdenum element, making it more corrosion-resistant, especially resistant to chloride (such as seawater, de icing salts) and acidic environments, suitable for harsh environments such as food, chemical, and marine.

rotation function

The cargo hook can rotate freely 360 degrees, making it convenient, fast, and flexible to hang and adjust the direction of goods, thereby improving operational efficiency.

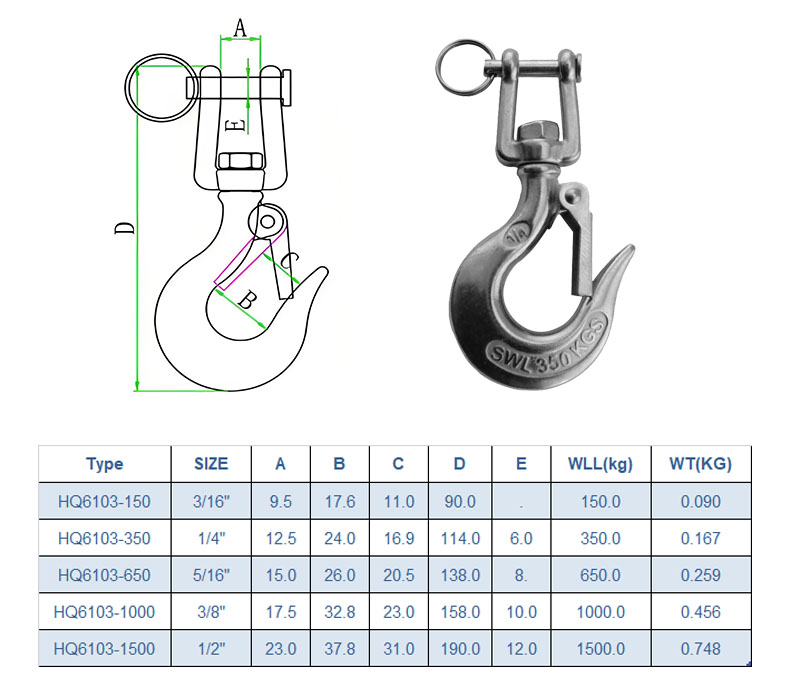

Fork installation

Designed for direct mounting on the fork of a forklift, it is easy and quick to install and disassemble, does not occupy additional device space, and has a wide range of applicability.

High strength and durability

Both types of stainless steel materials provide excellent strength and toughness, capable of withstanding heavy loads and impacts, and have a long service life.

cleanliness and hygiene

Stainless steel has a smooth surface, is not prone to accumulating dirt, is easy to clean, and meets the high hygiene requirements of industries such as food and medicine.

Summary:

304 hook: economical and practical, suitable for most ordinary humid, non corrosive environments.

316 hook: the king of anti-corrosion, designed specifically for more demanding and highly corrosive working environments.

Both greatly enhance the flexibility and efficiency of material handling through their rotating function and fork design.